CNC machining is a process that is used to create parts and products from a variety of materials. The process involves the use of computer-controlled machines to remove material from a workpiece and shape it into the desired product. CNC products are everywhere around us, making our lives easier. CNC is an amazing amalgamation of creativity and technology.

It is a process of creating parts using computer-controlled tools. This guide will teach you everything you need to know about CNC machining, from the basics of the process to the different types of machines and software. CNC machining has revolutionized the manufacturing industry, and it’s only getting more popular as time goes on. If you’re thinking about getting into CNC machining, or if you’re just curious about how it works, this guide is for you.

CNC Machining 101

CNC is short for computer numerical control. CNC machining is a versatile manufacturing process that can be used to create a wide variety of parts and products. CNC Machining uses different materials, including metals, plastics, and composites. It is a precise process that can create parts with tight tolerances. The history of CNC machining is fascinating. It had its humble beginnings back in 1941 but these machines weren’t so precise. The first machines for milling metals were created in the 1940s and used punched tape, which was commonly used at the time in telecommunication and data storage. Machines from this era were analog, meaning they were slow and inefficient. As digital technologies emerged in the 60s, it soon became more efficient to automate the process of milling metal.

Yet today, CNC becomes omnipresent and its future seems very bright. As technology improves and the demand for skilled workers grows, the role of traditional machinists has become less relevant. The demand for CNC specialists has been steadily growing. Organizations such as the Institute for Technical Trades offer training to equip machinists with the skills needed to work effectively in this field. In many industries, job prospects are excellent; some predict that future open job positions will be primarily occupations related to technology-based industries such as operating CNC equipment.

The CNC machining process begins with the creation of a computer-aided design (CAD) file. The CAD file is used to generate a computer-aided manufacturing (CAM) file. The CAM file contains instructions for the CNC machine on how to create the desired part or product.

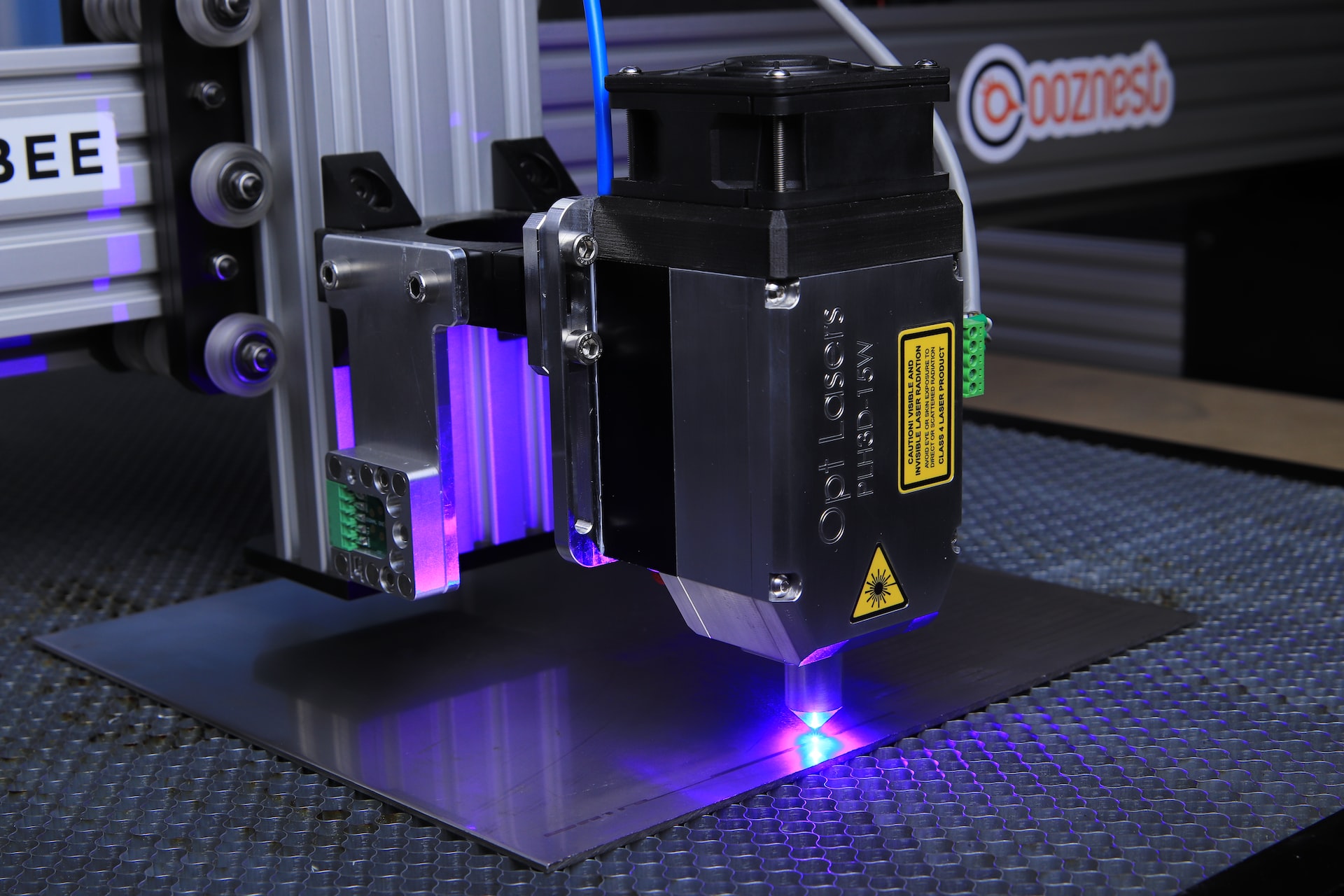

Once the CAM file is created, it is loaded into the CNC machine. The machine then uses cutting tools to remove material from the workpiece and shape it into the desired product. CNC machine helps you play with form

After the part or product is complete, it undergoes a finishing process, such as painting or plating. The finished part or product is then ready for use or assembly into larger products.

CNC Machining Tools: Milling, Drills and Lathes

The three primary types of CNC machining tools are CNC milling machines, drills and lathes.

Milling Machines: Milling machines are used to create complex, three-dimensional shapes from a variety of materials. These machines can be outfitted with a variety of cutting tools, including end mills, ball mills and face mills. CNC milling, or computer numerical control milling, is an advanced machining process that employs constantly-changing computerized cutting tools and high-tech control systems to produce custom-designed parts and products.

Drills: Drills are used to create holes in a workpiece. These holes can be used for a variety of purposes, such as threading or installing fasteners. Drill bits come in a variety of sizes and shapes, and can be made from a variety of materials, including carbide, high-speed steel and cobalt.

Lathes: Lathes are used to shape workpieces by rotating them against a cutting tool. This process is known as turning. Lathes can be outfitted with various attachments, such as chucks and faceplates, to accommodate different sizes and types of workpieces.

What is a CNC machine used for?

CNC machining is a process that uses computerized numeric controls to operate machine tools. This means that instead of being operated by hand, the machine is operated by a computer.

CNC machining is used for a variety of applications, including prototype development, production runs, and one-off parts. In prototype development, CNC machining can be used to create prototypes quickly and cheaply. Production runs are when CNC machining is used to create large quantities of parts. One-off parts are single pieces that are not part of a production run.

Is CNC hard to learn?

If you’re wondering whether CNC machining is hard to learn, the answer is both yes and no. The process of operating a CNC machine can be complex, but with the right training and practice, it can be mastered.

Like any skill, learning how to operate a CNC machine takes time and patience. But once you’ve got the hang of it, you’ll be able to produce high-quality parts and components with ease.

So if you’re considering getting into CNC machining, don’t be discouraged – it’s definitely worth the effort!