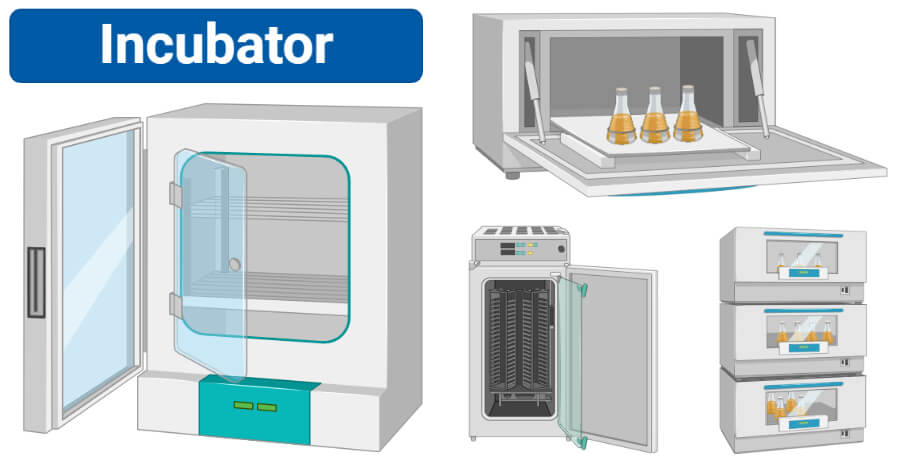

Incubators with a Biological Oxygen Demand (BOD) are a kind of testing apparatus used often in the field of microbiology. These incubators are utilized to both maintain and produce cell and microbiological cultures. It is applied for the purpose of maintaining temperature for the preservation of bacterial cultures, the development of test tissue cultures, and incubation where a high degree of continuous temperature precision is needed. These ensure that the conditions are accurate and constant across the whole chamber. This is the most essential pieces of laboratory equipment found in a variety of research facilities, hospitals, and other pharmaceutical laboratories is the BOD incubator, also known as a low temperature incubator.

What is Bod incubator?

BOD incubation testing, as well as testing for crystallography, is highly significant in today’s world. As selling the best bod Incubators, Bod incubator manufacturers in India units are designed to meet APHA specifications for Biochemical Oxygen Demand (B.O.D). Additionally, these incubators are outfitted with a mechanical convection system to guarantee even distribution of air, an overload security system, a temperature control controller, and safe operation high and low limit control mechanisms.

Basic working principal Behind a Incubator

Another term for BOD incubators is the name given to low temperature incubators. This is done in order to maintain the temperature that is necessary for the development of microorganisms and to make room for BOD testing. The refrigeration concept may be used to accomplish cooling of the incubator. A circuit that is based on a microprocessor is responsible for controlling the heating and cooling of the incubation chamber. In order to effectively control the system, the PID (Proportional Integral Derivative) concept is used. Incubators with a Biological Oxygen Demand (BOD) are often regarded as being among the most important pieces of laboratory equipment in medical facilities, pharmaceutical labs, and research facilities.

Purchases of BOD may now be made quickly and easily, and only from reputable and recognized Bod incubator manufacturers India. BOD Incubator units are adequately manufactured, and they are composed of corrosion-resistant stainless steel. These incubators are sometimes referred to as low-temperature incubators. Variety of movable cold storage containers that are perfect for seasonal or permanent storage of your products. These insulated, used refer units sit at ground level for easy access, and are manufactured with the highest standards to withstand the harshest environments. Such multipurpose refrigerated containers for sale are available and you can buy it at as per your business needs.

Features of BOD incubator

- Stainless steel is used for both the inside and exterior.

- Greater than 28.0 inches of Hg of vacuuming pressure

- Controlled by a microprocessor and using a PID algorithm

- Air heaters powered by electricity and attached to the outside surface

- A safety thermostat that guards against the temperature exceeding its setpoint.

- Closure method for doors with a single handle

- Vacuum Gauge That Is Simple to Read

- Large viewing window for doing quality control on the samples.

- Documents include an operating manual as well as IQ, OQ, and PQ ratings

- Because of the precision with which they are constructed and produced, BOD Incubators provide a consistent level of performance and have the appearance of being professionally made.

- A one-of-a-kind air circulation system, cooling system, full-view viewing glass door, and storage trays are all included.

- In the occasion that the temperature becomes too high or too low, the safety controller sensor will turn off the power supply while simultaneously sounding an audible and visible alert.

- Inside made of stainless steel, and either powder-coated mild steel or stainless steel on the outside.

- Interior brightness

Bottom Line

Bod incubator are not intended to be exposed to intense solvents, oils, or acids, or even sodium hydroxide in diluted form. When it is being operated, there is no heat transmission from the interior of the evacuated chamber to the things that are contained inside the chamber, unless the goods are lying directly onto one of the shelves. It is imperative that you do not position insulating material between a shelf and a vessel that is in the process of being heated.